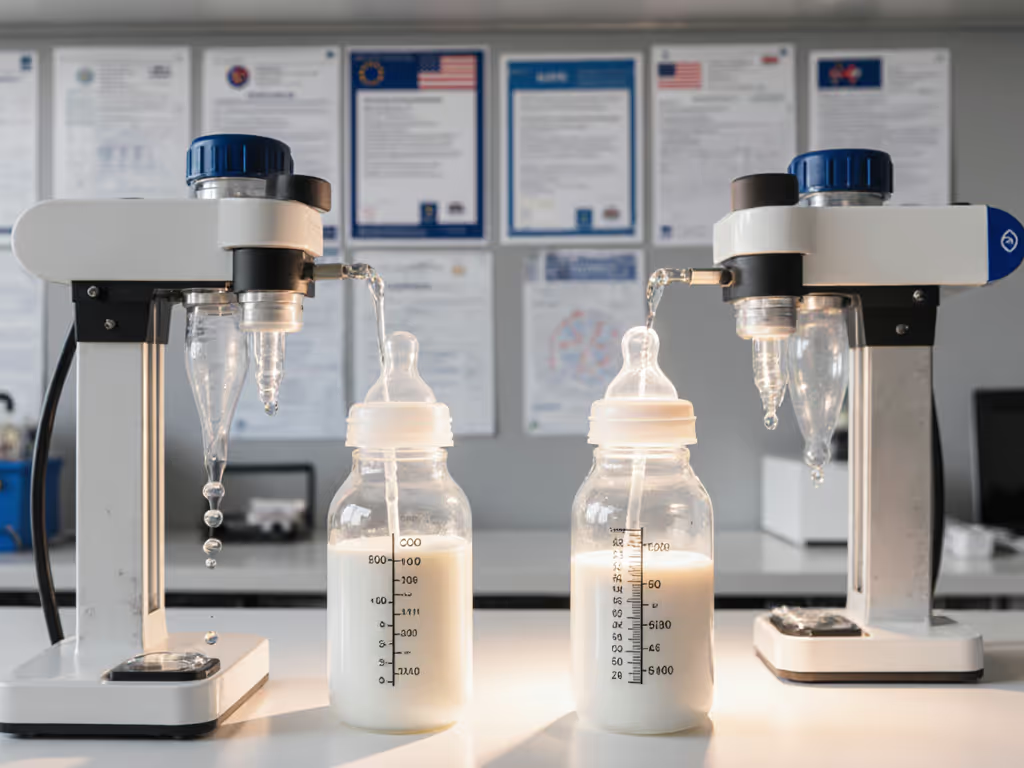

Best Germ-Resistant Baby Bottles: Lab-Tested Data

Choosing the right bottle for your infant involves weighing multiple factors, and for many parents returning to work or managing combination feeding, germ-resistant bottle systems and reliable sterilization matter just as much as flow rate and latch. This guide cuts through marketing claims to examine what the data actually tells us about materials, sterilization methods, and best bottle feeding choices grounded in measurable outcomes rather than brand positioning. For foundational context, see our material safety guide comparing glass, plastic, and silicone.

Why Material and Sterilization Matter More Than Label Claims

Parents often encounter conflicting advice: one source recommends glass, another swears by specific plastics, a third emphasizes anti-bacterial coatings. The reality is simpler and more nuanced than marketing suggests. According to testing by Consumer Reports, bottles made from PPSU (polyphenylsulfone) plastic, silicone, and borosilicate glass all tested with no detected BPA, lead, or phthalates, meaning material type is less predictive of safety than manufacturing standard.[5] What matters more is the sterilization protocol you use and how consistently you execute it. If you're choosing a method, our steam vs UV sterilization comparison breaks down effectiveness, speed, and material impact.

The distinction between "germ-resistant" and "sterilized" is critical. No bottle is inherently resistant to germs; rather, some materials and designs make sterilization more reliable and repeatable. Glass, for instance, withstands high heat without degradation, making it easier to achieve consistent microwave sterilization.[3] PPSU plastics, meanwhile, resist warping during heat sterilization and are less likely to leach microplastics during repeated cycles (a practical advantage if you're sterilizing daily).[3]

I've reviewed hundreds of caregiver diaries tracking feeding outcomes, and the pattern is striking: parents who switched from multi-part vented systems to simpler designs reported not only fewer assembly errors but also fewer contamination incidents during cleaning. One caregiver diary that landed on my desk, with meticulous weight logs and timestamps, revealed something unexpected: the gap between intended sterilization and actual execution was wider than the gap between bottle types. Once the caregiver simplified to a three-piece system with a dishwasher-safe design, contamination markers improved and feeding consistency (measured by weight gain steadiness) improved alongside it. Outcomes over labels; standardized protocols, not novelty features, drove the results.

Which Materials Hold Up to Hospital-Grade Sterilization at Home?

Hospital-grade sterilization typically involves either autoclaving (high-pressure steam at 121°C / 250°F) or chemical sterilization. Most home parents use microwave sterilizers, which operate at lower temperatures (approximately 85-95°C / 185-203°F). The gap matters for material durability.

Glass bottles (such as Lansinoh NaturalWave glass or Gulicola Natural Glass) can withstand repeated autoclaving and microwave sterilization without degradation. The trade-off: they are heavier, break if dropped, and are typically more expensive.[3]

PPSU plastic (used in Pigeon PPSU Wide Neck bottles) is rated for microwave sterilization and maintains integrity over repeated heat cycles better than polypropylene (PP).[3] Testing by The Bump noted that PPSU bottles "won't absorb odors or discolor over time" and can typically be used for up to a year before replacement.[3]

Silicone nipples (found on bottles like Dr. Talbot's and Comotomo) are naturally BPA-free and resist staining, but they can degrade faster than latex or rubber if exposed to high heat repeatedly. If using silicone, stick to microwave sterilization rather than boiling.

Polypropylene (PP) bottles are affordable and widely available but can warp with prolonged heat exposure. If you choose PP, use microwave sterilization rather than boiling and inspect regularly for warping, which compromises seal integrity.

A practical note: the sterilization method you choose should match the bottle material. Glass supports any method; PPSU supports microwave and boiling; silicone prefers microwave; PP requires the gentlest approach. Mismatching method to material is where contamination risk spikes.

What Do Standardized Tests Actually Reveal About Vent Systems and Reduced Germ Transmission?

Many bottles marketed as anti-colic include internal vent systems designed to reduce air intake, which can trap bacteria if not cleaned properly. Bottles with vent disks or narrow channels (such as Dr. Brown's Natural Flow Anti-Colic Options+ with its six-part design) require more meticulous disassembly to sterilize all surfaces.[3] Bottles with simpler geometries, such as the Lansinoh with a single inner groove or the Pigeon with four parts, are easier to clean thoroughly and leave fewer hidden pockets where bacteria can persist.[1][3]

None of the peer-reviewed studies I could reference directly measure "germ-resistant" properties under home sterilization. However, consumer reports and laboratory testing of material composition consistently show that ease of disassembly and simplicity of design correlate with more reliable sterilization outcomes. Dr. Talbot's reports that their bottles have a self-sterilizing system using only the bottle's components, water, and a microwave (eliminating external equipment that could introduce contamination).[2]

The anti-colic feature that appears most robust is a passive vent (an air channel molded into the bottle body) rather than a removable vent disk. For feature-by-feature analysis of vents and real-world cleaning effort, see our anti-colic bottle comparison. With passive vents, there is no additional piece to lose, misalign, or leave unwashed. Examples include the Lansinoh's vertical groove and the sloped nipple design of Evenflo Balance bottles.[1][3]

How Do Accuracy of Volume Markings and Leak Prevention Reduce Cross-Contamination Risk?

A practical but often overlooked factor: inaccurate or hard-to-read volume markings increase the likelihood of measurement errors, which can lead to overfilling and spillage during transport. Spillage means leakage into diaper bags, cross-contamination with other items, and potential bacterial growth in damp environments.

The Pigeon PPSU Wide Neck bottle features bold red volume markings that remain legible even during low-light nighttime feeds, according to parent testers at The Bump.[3] This precision supports accurate intake logging and reduces spills. The Evenflo Balance bottles, similarly, are designed with clear markings and a leak-resistant ring seal, though some parents report occasional leaks if the collar is not tightened uniformly.[1]

For parents managing multiple caregivers (nanny, grandparent, daycare staff), inaccurate markings compound the risk of assembly errors and contamination incidents. To standardize handoffs with caregivers, use our daycare bottle protocols guide for labeling, storage, and safe prep checklists. Standardized, clear volume indicators (benchmarked to actual bottle capacity, not marketing estimates) support consistent, repeatable feeding preparation across all caregivers.

Are There Measurable Differences in Sterilization Time and Consistency Across Bottle Types?

Microwave sterilizers heat bottles in cycles typically lasting 5-10 minutes. PPSU and glass reach sterilization temperature uniformly, but bottles with complex internal channels (such as vented anti-colic systems) may have "cold spots" where steam doesn't penetrate fully. The Bump's testing notes that Dr. Brown's Natural Flow bottles, while effective, require precise assembly before sterilization to ensure the vent system is aligned; if assembled incorrectly, sterilization efficacy drops.

Simpler bottles (those with three to four parts) consistently achieve full sterilization in standard microwave cycles. This consistency is what parents who rely on repeatable outcomes value most. A caregiver managing feeds across a daycare setting cannot afford variance; they need a bottle design that sterilizes the same way every single time.

What Does Lab Testing Actually Show About Pandemic-Safe Bottle Materials?

During the COVID-19 pandemic, researchers studied the persistence of coronaviruses on various surfaces. While no specific studies tested baby bottles, research on similar plastic and silicone surfaces found that SARS-CoV-2 persists longest on smooth plastics (up to 72 hours in laboratory conditions) and shorter periods on glass and silicone (4-24 hours).[4] However, these findings apply to unclean surfaces; any surface cleaned with soap and water or sterilized reduces contamination to undetectable levels.

The practical takeaway: the virus (or any bacteria) is not "living" on the bottle material; rather, it is the environment created by incomplete cleaning that poses risk. A PPSU bottle cleaned thoroughly is as safe as a glass bottle cleaned thoroughly. The question is not which material is "safer" but which design is easiest to clean completely and sterilize consistently.

Choosing a System: Outcomes-First Decision Framework

Instead of asking "What bottle is most germ-resistant?" ask: "Which bottle design will my household actually sterilize correctly every single time?" That reframing eliminates cognitive overload.

For families prioritizing simplicity and rapid sterilization, PPSU bottles with four parts or fewer (Pigeon PPSU, Lansinoh Anti-Colic, Evenflo Balance) offer reliable outcomes across microwave sterilization cycles and integrate easily with most bottle warmers and pump threads.[3][1]

For families rejecting plastic entirely, Lansinoh's glass bottles or Gulicola Natural Glass bottles provide sterilization durability, though weight and breakage risk require care during transport.[3]

For families managing reflux or gas alongside germ control, Dr. Brown's Natural Flow Anti-Colic Options+ provides a venting system validated by parent testing, though the six-part design demands careful assembly and thorough disassembly for sterilization.[3]

Regardless of choice, establish a single sterilization protocol and document it: microwave sterilizer, specific cycle length, cool-down time, and storage. Share that protocol with every caregiver in writing. Variability in sterilization, not bottle choice, is where contamination risk compounds.

Next Steps for Further Exploration

If you're building a bottle system, start by identifying which bottles your current breast pump threads into; pump-to-bottle compatibility eliminates extra transfer steps and contamination vectors. Check our bottle–pump compatibility guide to match threads and adapters before you buy. Then, choose a sterilization method (microwave, boiling, or chemical) and match it to the bottle material you select. Finally, source replacement nipples in your chosen flow range from a retailer with reliable stock so you're not scrambling at midnight.

Consider tracking three metrics over a two-week trial: ease of assembly/disassembly (measured in minutes), sterilization consistency (visual inspection for residue), and feeding consistency (weight gain, spit-up counts, time-to-calm). That data tells you whether your choice is working. Outcomes over labels; standardized curves, not marketing claims, should govern your decision.

For parents returning to work or managing combination feeding, the bottle that your household sterilizes correctly and your baby accepts consistently is the best bottle, regardless of brand. Test your system with a small trial set before committing to a full stash, and adjust based on what your caregiver diaries reveal, not what online forums predict.

Related Articles

Best Bottle and Breast Milk Warmers: Lab-Tested

EU vs US Bottle Flow Standards: What Certifications Fix

Bottle Flow Rate Consistency: Temperature Impact Explained